Everything about Plastic Random packing for corrosive applications

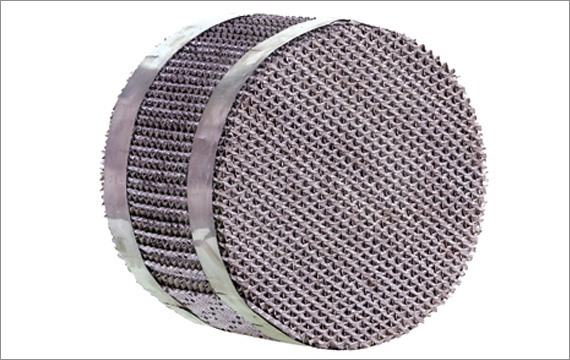

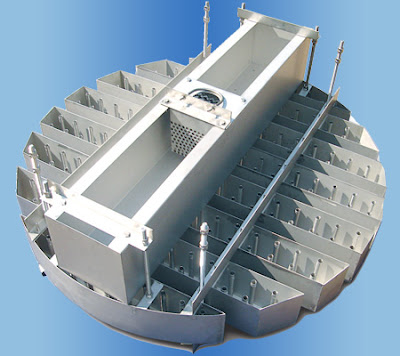

Earlier known as dumped packing and used popularly in the gas, chemical plants, and refinery random packing is traditionally used for the fractional operations. It has been used to increase the tower’s capacity, and therefore it is a cost-effective and efficient solution used from several decades. Its effectiveness is looked in the dehumidification of air where LiCl (lithium chloride) is utilized. With the innovations and new outcomes, random packing displays improved products for the new generations. Available in three different varieties (materials) plastic, ceramic, and metals based on different operational temperatures, the optimum utilization is made for the mass and heat transfer. In addition to better performance benefit, there are many other advantages of random packing. Below-mentioned is a few more benefits: - The pressure drop reduction throughout the column - Liquid holdup reduction in the column - C...