THE ADVANTAGES OF MASS TRANSFER PRODUCTS

Mass transfer phenomenon is a necessity for the big industries today. Therefore packing equipment needed for this mass transfer plays an important role here. Do you know there are different types of mass packing equipment’s? Whether it is column packing, random packing or structured packing they are beneficial to a different type of industries?

Today, they are the solution to the engineering problems faced by big industries. Finepac Structures Pvt. Ltd. Manufactures various kinds of products by applying modern technologies and deliver the best equipment’s that industries need.

TYPES OF MASS TRANSFER PRODUCTS YOU NEED TO KNOW ABOUT

There are many shapes and structures of packing equipment which have been made by Finepac structures Pvt Ltd. to satisfy the need of the industries today.

So, let’s get started and to have a look at it

· The first one is random packing, that includes metal packing (IMTP PACKING, FP-Pall Ring), Plastic packing’s (FP- Cascade Ring, Pall Ring, Star Pack Packing, Tellerette, and Super Saddle) and Ceramic Random Packing ( Ceramic Pall Ring, Super Saddle and Ceramic Saddle).

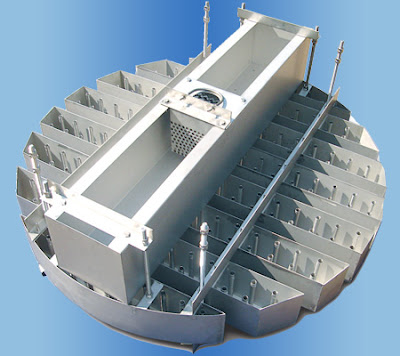

· Then comes, Structured Packing, which involves Laboratory packing, Grid packing, Corrosion Resistant Packing, and high capacity packing etc.

FIND OUT HOW THESE PRODUCTS WORKS

Just like the differences in the shapes of these equipment’s or products, the usage and advantages are also different. Now, let’s start with a random one and understand how they benefit the industries they are used in.

· RANDOM PACKING – Just like its name, the definition is pretty simple; they are not arranged by any column. The open nature of this packing ensures no blockage and is used for absorption, stripping, acid gas removal etc. They have high mechanical strength but are still inexpensive and the best way to increase power capacity. The FP- IMTP packing has a high strength to weight ratio and reduces foam generation with the low-pressure drop.

· PLASTIC PACKING–This kind of plastic packings are lightweight and not bulky. They are used for absorption, heat transfer and scrubbing services generally. They are also less expensive than metal packing. Plastic packing’s are popular due to high capacity but low-pressure drop characteristics. They are apt for high corrosion applications and show excellent efficiency when it comes to heat transfer services.

· STRUCTURED PACKING – The cost of these kinds of packing can be higher than the random packings but it is highly efficient. With a low-pressure drop and high separation efficiency, they are used for high vacuum distillation and absorption services.

· OTHERS LIKE COLUMN INTERNALS– The column packing system are easy to install and also easy to remove. They are also not that expensive and handle corrosive materials due to corrosion-resistant packing.

You must have got some general idea from the above points now. So not going into more depth here, it is evident how these mass transfer equipment has become a helping hand to industries for fulfilling their goals. At Finepac we are upgrading all our products with cutting-edge technologies every day. And with these mass transfer products, we believe the bright future of industries is in our hands.

Comments

Post a Comment