The Best Structured Packing With Finepac

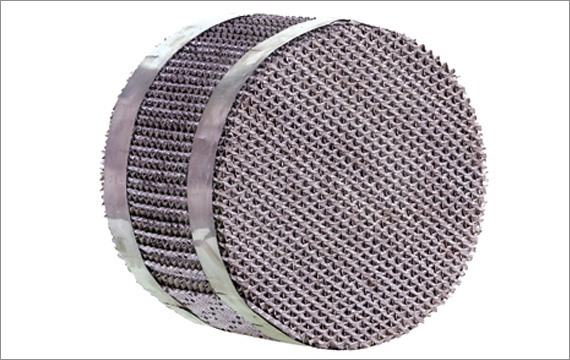

Structured packing manufacturers select substances which are created for chemical reactors, besides, to use in absorption and distillation columns. They include corrugated metallic plates, made to induce fluids on paths. The plan is intended to generate a vast surface area for contact between stages. Structured packing is created of many different materials such as corrugated sheets of wire gauze, or perforated , metal. The product is similar to honeycomb with flow stations that are likely making a surface area combined with a gas flow resistance. Enhancements are chosen to optimize liquid dispersing that is perfect for applications with reduced pressure. Packing trays are used when a column is undergoing a bottleneck problem. These trays are substituted using structured packing by structured packing manufacturers for three reasons: 1. They supply an additional place for the contact between vapor and liquid. 2. Better separation efficiency. 3. Structured packed col